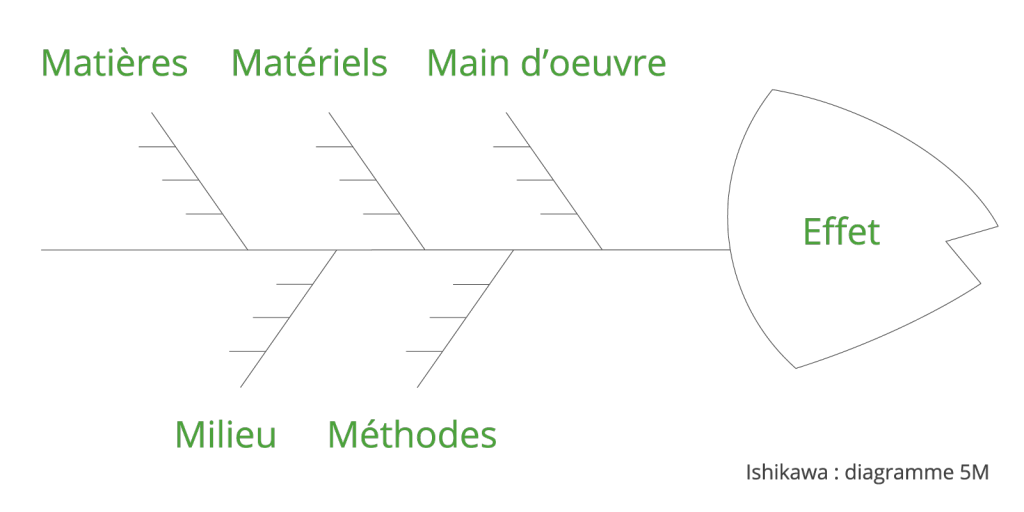

It provides a structured and systematic approach to identify and collate potential causes for an effect. OCLC 904826764.Ishikawa diagram can be applied in clinical fields and mental/ behavioural health proactively. Handbook of Lean Manufacturing in the Food Industry. Reliability engineering : a life cycle approach. Failure mode and effects analysis (FMEAs) for small business owners and non-engineers : determining and preventing what can go wrong. ^ "Fishbone diagram: Solving problems properly"."Thinking about causality." The psychology of human thought (1988): 92-115. "Determining the cause of quality problems: lessons from diagnostic disciplines." Quality Management Journal 5.2 (1998): 24-41. Improving complex systems today : proceedings of the 18th ISPE International Conference on Concurrent Engineering. Milwaukee, Wisconsin: American Society for Quality. ^ a b c Project Management Institute 2015, pp. 20–24, §2.4.4.2 Cause-and-Effect Diagrams.To help structure the approach, the categories are often selected from one of the common models shown below, but may emerge as something unique to the application in a specific case.Įach potential cause is traced back to find the root cause, often using the 5 Whys technique. The causes emerge by analysis, often through brainstorming sessions, and are grouped into categories on the main branches off the fishbone. A problem is a situation that bears improvement a symptom is the effect of a cause: a situation can be both a problem and a symptom.Īt a practical level, a cause is whatever is responsible for, or explains, an effect - a factor "whose presence makes a critical difference to the occurrence of an outcome". Smith highlights this and the common question, “Is that a problem or a symptom?” This question mistakenly presumes that problems and symptoms are contrasting categories, like light and heavy, such that something can’t be both. There can be considerable confusion about the relationships between problems, causes, symptoms and effects. It shows high-level causes that lead to the problem encountered by providing a snapshot of the current situation. Root-cause analysis is intended to reveal key relationships among various variables, and the possible causes provide additional insight into process behavior. ( June 2023) ( Learn how and when to remove this template message) Unsourced material may be challenged and removed. Please help improve this article by adding citations to reliable sources in this section. This section needs additional citations for verification. Mazda Motors famously used an Ishikawa diagram in the development of the Miata ( MX5) sports car. It is known as a fishbone diagram because of its shape, similar to the side view of a fish skeleton. The basic concept was first used in the 1920s, and is considered one of the seven basic tools of quality control. Ishikawa diagrams were popularized in the 1960s by Kaoru Ishikawa, who pioneered quality management processes in the Kawasaki shipyards, and in the process became one of the founding fathers of modern management. The defect, or the problem to be solved, is shown as the fish's head, facing to the right, with the causes extending to the left as fishbones the ribs branch off the backbone for major causes, with sub-branches for root-causes, to as many levels as required. Overview Sample Ishikawa diagram shows the causes contributing to problem.

Causes are usually grouped into major categories to identify and classify these sources of variation. Each cause or reason for imperfection is a source of variation.

Ĭommon uses of the Ishikawa diagram are product design and quality defect prevention to identify potential factors causing an overall effect.

Ishikawa diagrams (also called fishbone diagrams, herringbone diagrams, cause-and-effect diagrams) are causal diagrams created by Kaoru Ishikawa that show the potential causes of a specific event. To break down (in successive layers of detail) root causes that potentially contribute to a particular effect Causal diagrams created by Kaoru Ishikawa Ishikawa diagram

0 kommentar(er)

0 kommentar(er)